Bridges in ports and estuaries as we know them today have not always existed. Many other techniques had to be used to move large numbers of pedestrians and motorists when the means were lacking or the environment is unfavorable to bridges.

Ferries (BAC in french) have often been used to allow motorists and pedestrians to travel to opposite islands or shores. Today this solution is set up for long-distance crossings. We will take as an example the ferry going from Royan to Soulac which crosses the Garonne. This ferry can accommodate about 600 passengers and 150 cars and avoids more than 50 km of detour along the highway.

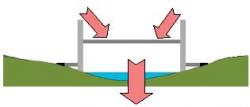

When a bridge of considerable height was needed, transporter bridges were used. Often used in the ’50s and ’60s the majority of transporter bridges are no longer running because of their supplementation by modern bridges. This is due to several reasons, including the fact that this type of bridge can’t move large amounts of motorists and requires a significant cost for maintenance. The transporter bridge is based on the principle of sliding : hooks and cables are attached to the deck and slide by on rails. This allows this bridge to move forward. We will use the example of the transporter bridge of Rochefort which passes over the Charente. It is the only transporter bridge still used today in France. It consists of four tall metal pylons of 66 meters, a deck 50 meters high and covers a distance of 175 meters long.

The science behind the bridges is not stagnant: in a few years new innovative technical solutions may be used to replace the bridges. In the city center of some cities and urban centers cable cars are used. This is the case in Brest, which houses the first urban cable car in France. Costing more than 20 million euros, the crossing lasts three minutes, rising at speeds of 120 km / h. It travels a distance of 460 meters and is able to carry about 1,200 passengers every hour. This is just one of dozens of proposed solutions that can be put in place in the future.